TAYA technology enhances lagoon and pond-based wastewater treatment

Stabilization pond systems constitute the simplest form of wastewater treatment, have been in use for more than a hundred years, with thousands of them still in operation in the USA and Europe, treating municipal and industrial wastewater.

There are several variants of stabilization pond systems, such as anaerobic, facultative, aerated and maturation. Two or three types of ponds are commonly arranged in series in different combinations, to serve specific treatment goals and site conditions, with correspondingly different levels of operational simplicity, energy consumption and land requirements for each of these combinations.

For example, a treatment site may choose to treat its wastewater with a single very large facultative lagoon, or with an anaerobic lagoon followed by a facultative lagoon resulting in a smaller total volume and land requirement, while maintaining the same negligible energy consumption.

However, despite the variety of lagoon-based treatment configurations, they end up very large, or if less so – they have high energy requirements; and all lagoon systems perform reasonably well at higher temperatures but are less applicable to nutrient removal at lower temperatures. These shortcomings of conventional lagoon-based systems become more relevant with current requirements for nutrient removal, in combination with energy efficiency preferences and land limitations. Thus, there is need for an alternative, lagoon compatible, low energy, low attention process, with nutrient removal capabilities.

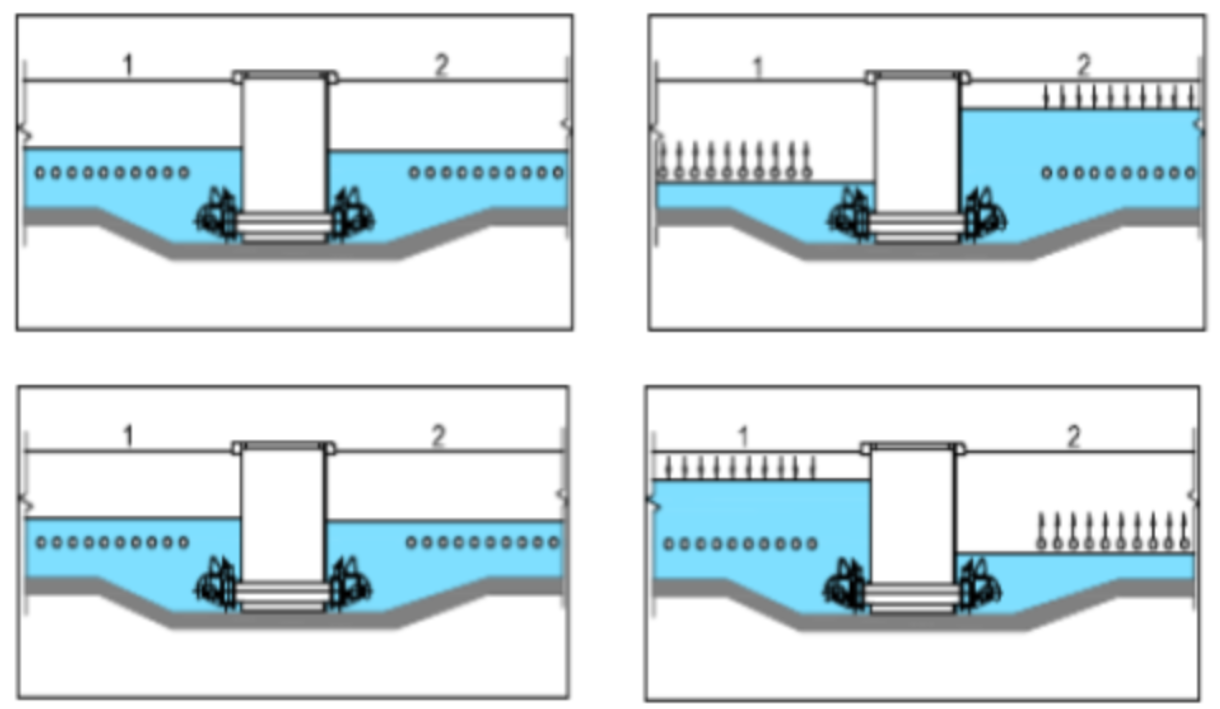

TAYA is a reciprocal constructed wetland based on passing the volume of water between a pair of basins filled with media such as gravel or plastic media (see figure 1). The filling and draining process provides passive aeration along with mixing for mass transfer, while the media also retains suspended solids to produce effluent with low TSS. The mixing combined with aeration over the media in the basins, provided by the filling and drawing cycles, supports biofilm-based processes for removal of organic matter as well as nitrogen. The frequency of the cycles, in terms such as the number of cycles per day, facilitates conditions for both nitrification and denitrification, to comply with total nitrogen requirements. The fill and drain cycles are performed by two propellor pumps with low energy consumption. Thus, TAYA maintains the advantages of extensive treatment – namely minimum electromechanical equipment, low energy consumption, easy to operate and no daily sludge handling, with a smaller footprint than other extensive lagoon-based processes.

Figure 1: reciprocal flow between two sides of a TAYA basin

Table 1 compares % removal of major regulated pollutants for different process configurations, all based on different combinations of lagoons in series. The TAYA process is presented on the last column (#6). In the last two row, table 1 presents typical land and energy requirements for each process configuration, in normalized terms.

Table 1: comparison of different process lines

Adapted from: “Biological Wastewater Treatment Series, volume three – Waste Stabilization Ponds”, by Marcos von Sperling, IWA Publishing, 2007

It can be concluded from table 1 that a TAYA single stage lagoon is about 10 times smaller than any series of non-aerated lagoons, at the expense of a relatively small energy consumption, whereas compared to aerated lagoons it has about half the energy consumption. Furthermore, TAYA has higher pollutant removal performance than all lagoon-based combinations, with respect to all pollutants (except coliforms removal compared to a process including maturation ponds).

Obviously, TAYA may be coupled to other lagoons where practical, such as anaerobic pretreatment as noted in column 6, or maturation post treatment. However, TAYA may be, and has been, coupled with more intensive pretreatment and post treatment units such as a septic tank or fine screens and media filtration respectively.

Therefore, TAYA proves to be an advantageous component in lagoon-based systems, and especially as an alternative for upgrading and retrofitting lagoon-based wastewater treatment operations for capacity increase and/or effluent quality improvement. Details and examples for retrofit projects will be provided in a separate publication – stay tuned.